Table of Contents

Requirements for Biostratigraphy at the Wellsite

All three major biostratigraphic techniques – micropaleontology, nannopaleontology and palynology – can be carried out at the wellsite to provide “real time” stratigraphic data. As far as the scientific requirements are concerned, these are relatively minimal. The scientist would require working space to sit and use the microscope.

In the case of sample processing, micropaleontology and nannopaleontology require facilities which are generally easily accessible on the rig. Access to running fresh water and a means of drying samples – either by electric hotplate or oven – are needed. Such facilities are often found in the “Mudlogging Unit” which is connected to rig supplies for electricity and running fresh water. It is common for the wellsite biostratigrapher to process their samples in the mudlogging unit and sometimes perform the microscope analytical work there as well, although many modern logging units lack available space of a “visitor”. In such cases the biostratigrapher often works in the rig offices and uses the mudlogging unit for sample processing only.

Because of the relative ease of wellsite biostratigraphic operations for micropaleontology and nannopaleontology, such operations can be mobilised at relatively short notice as everything can more-or-less be hand-carried to the wellsite.

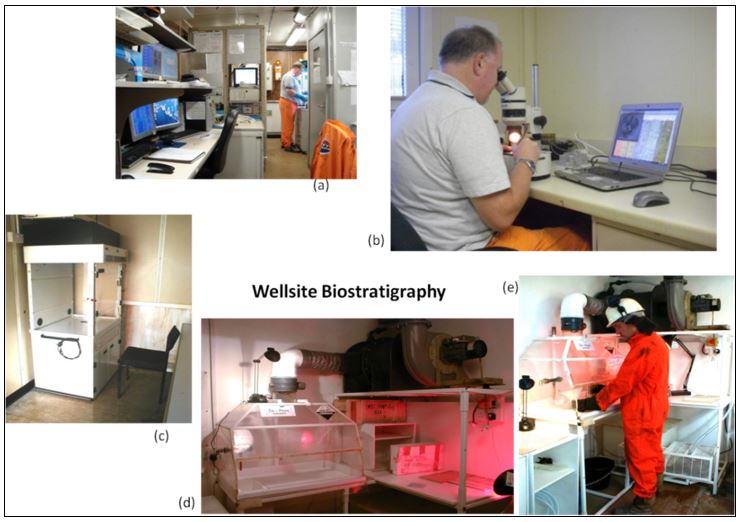

Aspects of wellsite biostratigraphy: (a)- micropaleontological sample processing in the sink of a mudlogging unit; (b)- a wellsite biostratigrapher analysing samples in the wellsite geologist’s office; © and (d)- processing equipment inside a wellsite palynology laboratory; (e)- a palynological laboratory technician working at a fume cupboard.

On the other hand, wellsite palynology requires complex additional equipment to deal with the sample processing side of the operation. Samples required for palynological analysis need to be processed by a variety of different chemicals – mainly strong acids and alkali solutions. It is the handling and disposal of these corrosive and toxic chemicals during sample processing (normally these occur in purpose-built laboratories) that provide challenges for wellsite operations. Such equipment (fume cupboards, vapour scrubbers, neutralising and holding tanks etc.) has been effectively miniaturised and built into offshore-certificated, pressurised units. These can be shipped to the rig and hooked into rig electrical and water supplies. They are usually manned by a laboratory technician as processing is an intensive process, and which the palynological scientist (palynologist) would not have time to undertake themselves as well as analysing the processed samples.

A nannopaleontologist works in a purpose-built biostratigraphic unit on a well west of Shetland. The presence of the fume cupboard shows that it is set-up for palynological processing. These units are normally only used at rigsite for longer-term, multiwell contracts. For “one-off” jobs not involving palynology, biostratigraphers usually work in the Mudlogging Unit or in offices inside the accommodation area. The polystyrene cups contain cuttings samples for the biostratigrapher, caught and provided by the Mud Loggers.

Some companies have experimented with “acid-free” palynological preparation techniques with varying degrees of success but even this technique requires equipment which cannot be hand-carried to the wellsite and also requires a degree of connection to rig services.